When your furnace is working as it should be, it’s easy not to think about the heat exchanger, which is the largest component of the furnace. Inspecting the heat exchanger is a very important part of our safety and efficiency furnace check-ups, as time and use take their toll and can result in cracks or holes forming on the heat exchanger. This can cause a furnace to produce incomplete fuel combustion and unsafe levels of carbon monoxide (CO), which means that the heat exchanger is important both for the functionality of your furnace and the safety of your home.

What does the Heat Exchanger do?

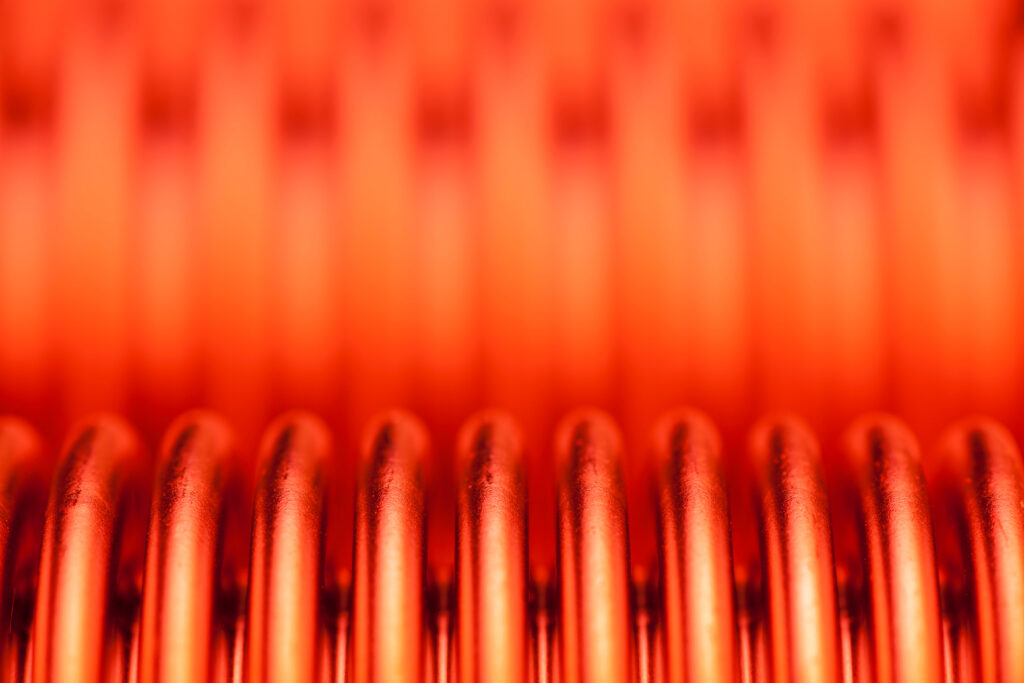

The purpose of a heat exchanger is to safely transfer heat, and they can be found in refrigeration, space heaters, chemical plants, and power stations, to name a few examples. However, we’re focused on the heat exchanger found in a forced-air heating system.

When your furnace burns natural gas or propane, its combustion by-products (flue gas) enter and travel through the heat exchanger. The metal of the heat exchanger heats up as the gas heads toward the exhaust outlet of the furnace. At the same time, the hot metal heats the air circulating over the outside of the heat exchanger.

Furnaces that are 70-80% Efficient have one primary heat exchanger. This part contains the hottest gasses and is found closest to the burners in a furnace. As a result, the flame and heat from the burners subject the primary heat exchanger to the most stress, which can lead to cracking and heat stress over the years.

Furnaces that are 90%+ efficient contain a primary and secondary heat exchanger. The combustion exhaust travels from the primary to the secondary heat exchanger, which releases more heat from the flue gas and produces water vapor. The change of state from water as a vapor to a liquid releases latent heat in the secondary heat exchanger, bringing the furnace to a higher level of efficiency. Secondary heat exchangers are usually constructed from stainless steel or a coated steel capable of withstanding heat, moisture and acid.

Heat Exchanger Safety

Most Furnace heat exchangers should last between 10-20 years, but factors like improper design or installation or lack of maintenance can cause wear and tear that decreases that life expectancy. Once cracks or holes are worn into a heat exchanger, dangerous levels of carbon monoxide can be released into the home. Carbon monoxide can enter your home through poor venting or leaks in the heat exchanger, and can cause very serious illness or even death.

We suggest installing carbon monoxide detectors on a wall about 5 feet above the floor, avoiding the areas directly next to or over your furnace or fireplace.

Heat Exchanger Maintenance

Unless your furnace is not functioning properly or your carbon monoxide detector is going off, it’s nearly impossible to know if your heat exchanger has developed problems without direct inspection or CO testing. This is why we highly recommend having your furnace checked regularly (at least once per year). A heat exchanger inspection and combustion analysis can determine whether the furnace is operating safely.

Our HVAC experts have cameras for a visual inspection of your heat exchanger as well as combustion analysis equipment to ensure the safety of your furnace and your home, and will do so during your furnace check-up.

Call today to schedule a furnace tune-up with our heating & cooling experts!